In addition to keeping your restoration project off the ground, your restored car’s suspension is a critical safety item. Suspension components in an older car have generally been exposed to more extreme stresses and adverse conditions than any other part of the car. Additionally, advances in suspension technology over the years have produced modern cars that are much more forgiving of driver error, and your restoration will benefit from careful attention to detail if you plan to drive your classic when it’s finished.

The good news is that consumable parts such as bushings and bearings are widely available for restoration purposes, and these parts are often substantially superior to those available when your car was in general use. With some simple steps, you can restore your car’s suspension to better-than-new condition.

Another piece of good news is that older suspensions are simple in their design. There’s not a lot of adjustability in most older designs, so you don’t have to worry too much about getting things back in the right orientation.

|

|

Warning... |

|

Automotive suspensions use tremendously powerful springs that are held under compression when normally installed. Do not attempt to release any automotive spring without the proper tools and instructions or you could seriously injure yourself or even be killed. It costs just a few dollars to have a professional shop install front springs, and it’s money well-spent.

|

If you’ve followed the instructions provided at this site for disassembling and recording notes about your car’s construction, and had your suspension parts cleaned, you’re ready to dive into the restoration process.

Before you paint, coat, or start to reassemble your suspension, it pays to have all stressed parts checked for cracks. Depending on your particular suspension design, this means hubs, spindles, king pins, axle shafts, lug studs, A-arms, and other control arms. Be sure to carefully inspect the suspension attachment points as well! We know a man who lost his well-restored classic when the rear spring attachment points ripped loose of the body while he was turning a corner. Old steering knuckles, spindles, and hubs are especially prone to cracking. Consider every pothole and rock that has struck those components in their long life!

Crack-checking is easy to arrange--any good machine shop can do it, and if you need a recommendation, talk to your alignment professional. Crack checking usually involves a process called magnafluxing: spraying a dust or paint-like substance on the part and inspecting the surface under a black light for accumulations of the dust in cracks. Tiny breaks that are invisible to the naked eye literally glow under the ultra-violet light.

When you find a cracked component, it may be possible to weld or otherwise repair it. Do not attempt to repair suspension parts unless you are an experienced professional. To do so is flirting with disaster. If you end up replacing a part, be sure to ask if the part has been crack-checked! In extreme cases, you may have to have a part made which should also be done only by an experienced professional.

Once you are confident in your parts, you can paint or powder coat them and prepare for reassembly. Here is where you can bring your suspension back better than new. Among the many advances in automotive technology of the past decades, suspension bushings you purchase now are often made of modern materials that will outlast your restoration. These parts are also generally hidden from view, so they won’t cost you points. If a bit of the bushing is visible, you may be able to get the new part color-matched. Use a silicone based lubricant on rubber bushings and good modern grease on your new bushings to keep them from squeaking.

If your spindles and kingpins can be rebushed with new bronze bushings, be sure to have that done. Make sure that any necessary reaming is included in the rebush work order. Similarly, if your hubs survived the crack check, you may need to have oversize bearing races installed--the receivers for the bearing races are often expanded beyond the stock specification due to years of use. In some cases you can now replace your original bearings with permanently lubricated bearings, reducing your need for messy grease. Again, your local machine shop can help with bearing work.

You will want to locate a quality automotive spring shop to restore or replace your car’s springs. All metal fatigues eventually, and steel alloys and spring-making technology have advanced since your car was new. A professional spring shop can re-temper and re-arch your leaf springs and order or custom-twirl coil springs for you. If your car uses torsion bars, these can also be replaced with as-new components.

When it comes to reassembling the suspension, be sure to use a sturdy spring compressor for all coil springs. Luckily, older cars most often use leaf springs, which are easier and safer to install. Take your time and use new hardware to reassemble your suspension, and be sure to use new ball joints on your front end, if your car uses those. You can re-bush everything on your car but the effort is wasted if you re-use old ball joints.

Products such as Loctite are a great idea. Use the red-colored “Permanent” Loctite on suspension components to keep them in place. “Permanent” is unlikely to fail, but you can remove those fasteners later, if needed.

Lastly, buy yourself the best shock absorbers you can find that are appropriate to the car. Lever-arm shocks are usually rebuildable. Companies such as Apple Hydraulics, Inc. typically provide two rebuild methods: “Rebuild and Return” and “Exchange.” With the latter method you purchase rebuilt shocks from their stock--you then send in your old shocks to receive your core deposit. Tube shocks are usually less expensive to replace and modern tube shocks can be painted to match the originals. If your car is old enough to use friction shocks, make sure you restore (or re-create) the friction plates and adjust them properly.

If you’ve done everything right, you’ll have a “new car” steering and road-holding feel at least as good as the day it left the factory. A taut, crisp feel to the suspension will increase your driving enjoyment and make your restoration all the more valuable.

|

|

DO |

- Thoroughly inspect and crack-check all suspension hard parts

- Renew all bearings, seals, bushings, and ball joints

- Have new springs made if the originals are tired

|

|

DON’T |

- Don’t wait until your car is almost finished to think about your suspension

- Don’t assume that stressed parts are structurally sound

- Don’t work with loaded springs without proper tools and safety precautions

|

|

|

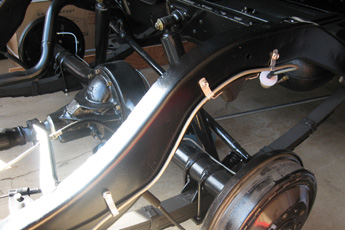

The Popular Restorations feature car suspension turned out well--one of the few areas of the restoration that did not require more attention than anticipated.

The front suspension parts came from Kanter Brothers including the bushings and seals and the rebuilt Delco double-acting lever shock absorbers. As you can see from the photo these shock absorbers also serve as the upper control arms, a design used by General Motors, Nash, and Packard from the mid 30s through the mid 50s. Apple Hydraulics is the largest rebuilder of this style shock--if I had it to do again I’d probably order from them.

The most unpleasant aspect of the front suspension restoration was taking apart the grease and dirt encrusted parts. Once the pieces were separated I took them, including the front coil springs, to the powder coater. How nice it was to pick up pristine parts when they were done.

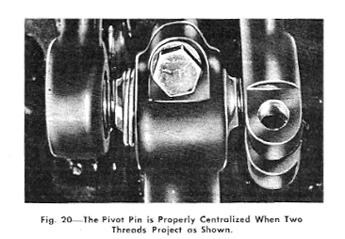

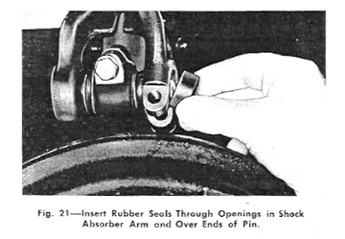

Although the Packard service manual had a good section on the front suspension, the assembly still took a while to figure out. I was initially disturbed by the fact that the seals for the adjustable control arm bushings seemed to have only one position where they would adequately protect the lubricated joints.

I adjusted each bushing to its central position, where the seals would be fully protective. I was afraid that the subsequent front end alignment would create gaps where dirt could enter. As it turned out, the car drove perfectly straight before the alignment and the alignment mechanic didn’t need to adjust anything except to make a minor change to the tow-in.

Benz Spring Company of Portland, Oregon serviced the rear leaf springs which included cleaning, testing, arcing, painting, and new separator pads. It was a bargain at about $80.00. Steele Rubber had the appropriate rubber bushings and Max Merritt provided the tube shocks. Packards of that era have a lateral shock absorber that goes from left to right, sometimes called the fifth shock. The lateral shock can be rebuilt but the project car’s was not leaking and still seemed to have a fair amount of resistance; so it got cleaned, painted and reinstalled.

|

|

|

Steve Olson - Shop Foreman

934 SE Sandy Blvd.

Portland, OR 97214

503-234-9797

PR: What are the suspension issues involved in a restoration project?

SO: They have to decide if they want to keep the vehicle to period, or if they want to upgrade to new technology, with coilover shocks, or change from straight axle to independent suspension. With the new technology, the ride is going to be better but there can be some more problems making sure it all goes together properly. For example, so you don’t have bump-steer problems and everything is sitting in the wheel wells the way you want. That’s probably one of the biggest problems we encounter.

PR: If someone is keeping their car absolutely stock, what should they plan to do?

SO: If you have something with a leaf spring, there are spring shops that can build new springs to period specifications. Coil springs are harder, but there are custom spring makers that can make them accordingly.

PR: How about bushings and other parts?

SO: Most places are going in with nylon inserts. It’s newer technology, but it’s not visible in a classic restoration.

PR: Is there a problem with stress on older suspension components while using modern tires?

SO: People have to understand the technology of working on older vehicles. The technology has come so far even in the last 10 years. So when you start talking about technology from the 20s, 30s, 40s, even from the 1960s, it’s very archaic. A lot of people think that if they rebuild a vehicle, it’ll be good, but it won’t drive like a new car. The technology has come so far, that it’s day and night.

PR: In general, where should people look for good suspension parts?

SO: Clubs are a good resource. People who build old cars and have built more than one know where these parts are. Plus, if they see something that they know is hard to get, they latch on to it, so club members have those parts on the shelf.

PR: Any other advice?

SO: Start from the ground up. Start with the suspension and get it done before you work on other parts. We get so many vehicles in our shop where they’ve finished everything up and we find that they’ve misplaced a bracket or that there’s frame damage they didn’t notice.

|

| Click on any item below for more details at Amazon.com |

|

|

|

Fred Puhn

How to Make Your Car Handle

HP Books, Paperback, 1976 |

|

A good book that helps you to understand the nature of a good handling car: good tires, alignment, lowering the ride height, springs, anti-roll bars, shocks, brakes, etc. The book is dated but that may not be a drawback for those restoring older cars.

|

|

Alan Church, Tom Denton

Suspension and Steering

Prentice Hall, Paperback, 2003-07-21 |

|

This book is part of the Automotive Technology: The Electronic Classroom learning system and is based on ASE guidelines and NATEF tasks. Included are shop worksheets, a glossary (English and Spanish), and hundreds of practice ASE-type test questions.

|

|

Don Alexander

High-Performance Handling Handbook

Motorbooks, Paperback, 2002-04-27 |

|

A definitive handbook on suspension theory, design, modification and tuning. Shows how to lower and stiffen your car for the best handling possible. High-performance street, autocross, road race and drag racing suspension setups are covered in detail.

|

|

|

|