Your car’s electrical system takes in a wide variety of parts and components. Everything from the starter motor to your ignition the light over the license plate to the cigarette lighter comes under the general heading of electrical parts.

This article focuses on the big, heavy components that generate and use electricity specifically to keep your car’s engine running, and on the special components of your ignition system. These include the generator (“dynamo” is another term used in many older cars) or alternator, voltage regulator, and starter motor.

When you took your engine in to be checked and probably rebuilt, either you or the engine shop removed your engine electrical components. Your first step is usually to test these components, and that process is different based on whether the components are on the car or removed.

If your components are already off the car, take them to a reliable automotive electrical shop for testing. These tests are more conclusive than tests you can perform, and can often reveal weakness or intermittent failure problems. Some general-purpose automotive shops and parts stores can also test these components for you.

If the components are still on the car, you want to ensure a fair test. A bad battery, unknown drains on electrical power, or increased resistance in the wiring can all affect a component test, so make sure you’re using a fresh battery and if possible, all new wiring to perform these tests. You don’t have to rip out the old stuff, just hook up new wires for the purposes of the test.

|

|

Hint... |

|

Make an investment in a battery and generator tester. A battery tester has two big clips similar to those used on jumper cables. If you hook it to a battery and turn it on, the gauge tells you how many volts the battery can deliver under load. A weak battery will start out delivering 12 or more volts, but quickly drop below 10 volts.

Battery and Alternator Tester

You can also use the same box to test a generator or alternator by connecting the clips to the positive and negative poles on the generator or alternator and reading the output. For a 12-volt system, a healthy generator or alternator should read between 13 and 14 volts. A 6-volt system should read up to about 7.5 volts.

|

To test a starter motor, connect a battery up with new cables and then use a remote starter trigger (you can buy them at any auto parts store) to test whether the starter has enough torque to spin the engine under load. Testing a generator is a little more tricky. The engine has to be running to test the generator fully installed. Use your charging system tester or a good volt meter.

|

|

Hint... |

|

One way to perform a basic test an alternator in the field is to take a steel screwdriver and hold it just in front of the central rotating shaft. This is the armature shaft, and as it spins, the magnets in the body of the alternator create a magnetic field in the armature wire windings. You can feel this field by holding the screwdriver about 1/4-inch from the end of the shaft. The screwdriver tip will be attracted to the shaft. If the shaft does not magnetize, then chances are your alternator isn’t working correctly.

|

Many older cars that use generators also feature a separate voltage regulator. Alternators generally have an internal regulator. External voltage regulators are the most difficult component to diagnose yourself. The danger with a faulty voltage regulator is that a bad regulator can kill your generator, so the two components are best tested professionally and as a unit. If either component is bad, rebuild or replace both of them.

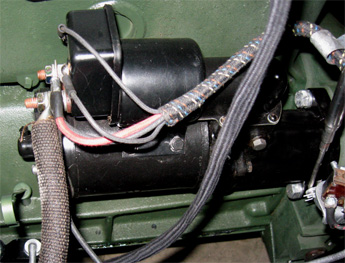

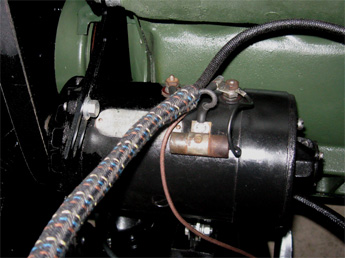

1940s Delco Starter

Older generators and starter motors can often be rebuilt by the home restorer. Typically, the restoration process includes replacing the bushings and bearings that hold the armature that spins within the component housing, and also the brushes that make contact with the armature. Replacing those parts, together with a thorough cleaning and inspection, can often refresh an older generator or starter to as-new condition. Put on a new coat of paint and the component is ready for further service.

1940s Delco Generator

Newer components such as alternators are not designed to be serviced by the consumer, however, and so with those you must pursue a replacement strategy. Luckily, these are also more likely to be available in new or professionally rebuilt condition.

Your best bet for purchasing new or rebuilt components is to locate an automotive electrical specialty shop in your area. They can order many vintage parts that are no longer available through conventional parts stores.

|

|

DO |

- Have each component tested to determine if it’s working at its rated capacity

- Have each component cleaned and restored by an expert

- Pay special attention to corrosion on connections

|

|

DON’T |

- Don’t assume that a component is OK because it seems to be working

- Don’t rely on used parts to work reliably

- Don’t simply paint over an old component as a restoration

|

|

|

When I started restoring the Popular Restorations feature car I had every intention of rebuilding the generator and starter myself. I even purchased the rebuild kits from Kanter Auto Products and disassembled the generator. But then I got to thinking about it. To do it right the commutator (the cylinder of copper blocks on the armature) should be turned. That is, it should be machined down so it’s smooth, even, and shiny. Also, I wasn’t sure whether to undercut the mica between the commutator blocks--I know in some cases you are not supposed to undercut but I couldn’t remember which cases. While looking on the web for my answer I read an article that recommended checking the tension for the brush springs. In my youth I wouldn’t have worried about these minor details; but for the Packard restoration I wanted everything to be as close to new as possible. So I decided to let a professional do it. I put the pieces in a box and delivered it to PMX (see the interview on this page).

The rebuilds were not that expensive and now that it’s done I feel more confident in my electrical system than if I had rebuilt the starter and generator myself. The starter cranks the engine over at a good speed, especially for a six volt system. Someone in my Packard club said that if everything is in proper working order there is no reason a 6 volt system should crank slowly. And I agree!

|

|

|

Bill Jungck, Owner

8420 SE Hinkley Ave.

Happy Valley, OR 97086-3616

Phone: (503) 777-7172

PR: If someone is restoring a classic car, what would you advise them to do with their charging system and starter?

PMX: With an older car, it’s usually a generator, rather than an alternator. If the car’s been sitting for a while, it’s good to get the generator and starter cleaned up and rebuilt to get the gum and spiders and bird’s nests out of them. This is just to get things working the way they’re supposed to.

PR: What about Voltage Regulators?

PMX: The job of the regulator is to monitor the voltage and keep it up around 14 volts.

PR: Can a bad regulator destroy a generator?

PMX: That depends on how the regulator fails. If the regulator doesn’t control the generator, it can overcharge and burn out the armature. But if it fails and doesn’t charge, then the battery goes dead, but you haven’t damaged the generator.

PR: Can someone test a generator at home?

PMX: You need to have something that will test for six volts, if it’s an older car. The battery should show about 6.2 volts, or 12.6 volts on a 12-volt battery. Then if you fire up the car it should go up 1-2 volts if it’s charging. For a 6-volt system, you want to see 7.2 to 7.5, and a 12-volt system should show about 14 to 14.5 volts. Then I usually have people turn on the heater and the headlights and rev the engine a bit, and you see a drop down to about 13 volts at the battery. But you have to have 13 volts to be sure you’re not running off the battery.

PR: If the charging system is not working, what do you do?

PMX: In most cases, I rebuild your components. I test both the regulator and generator and test them both, then rebuild from there.

PR: How about starter motors - what do you do there?

PMX: I rebuild a lot of them. Some of them I’ll convert from 6-volt to 12-volt operation, if people are updating their cars. I’ll go through the starter and put in new brushes and bushings and clean everything up. Sometimes we replace the solenoid or the bendix gear. One important thing is that if they stay with a 6-volt system, I make sure it’s got a 6-volt cable, because those have to be about twice as big as a 12-volt cable to run the starter correctly.

PR: Any other good advice?

PMX: Keep your battery charged up. Try not to jump a car with a flat battery and then use your charging system to charge up the battery. It’s better to use a battery charger to do that, and it’s hard on your alternator or generator. And one more thing, make sure you’ve got good grounds, especially from the engine block to the chassis. A lot of times those will get disconnected and then you’ve got a ground path that runs through the throttle cable or something. So, make sure those grounds are in place.

|

| Click on any item below for more details at Amazon.com |

|

|

|

Tony Candela

Automotive Wiring and Electrical Systems

S-A Design, Paperback, 2009-04-15 |

|

This book covers the basics of electrical principles and describes the required tools and equipment. It is your essential guide for such tasks as wiring a hot rod from scratch, modifying muscle car electrical circuits for cooling fans and/or power windows, or adding a premium stereo and other conveniences to modern performance cars.

|

|

Matt Strong

Custom Auto Wiring & Electrical HP1545: OEM Electrical Systems, Premade & Custom Wiring Kits, & Car Audio Installationsfor Street Rods, Muscle Cars, Race Cars, Trucks & Restorations

HP Trade, Paperback, 2009-04-07 |

|

This book covers electrical theory, wiring techniques and equipment, custom wiring harnesses for racing, hot rods and restorations, pre-made wiring harnesses, special electrical systems (navigational, audio, video), troubleshooting common electrical problems, dashboards and instrument, and trailer wiring.

|

|

Jim Horner

Automotive Electrical Handbook

HP Trade, Paperback, 1987-01-01 |

|

This is the fundamental book on automotive wiring and electrical systems. All the bases are covered here for restoration or custom work. If you need to completely rewire a car, this is the book to have.

|

|

Haynes

Haynes' Automotive Electrical Manual

Thomson Delmar Learning, Paperback, 1999-01-15 |

|

A complete guide to electrical system troubleshooting, repair, maintenance and rewiring. Clear step-by-step instructions and hundreds of photos show you how to do a professional job yourself.

|

|

Tracy Martin

How to Diagnose and Repair Automotive Electrical Systems

Motorbooks, Paperback, 2005-11-10 |

|

Tracy Martin, an ASE (Automotive Service Excellence) Certified Master Technician, explains the principles behind automotive electrical systems and how they work. Several hands-on projects take readers on a guided tour of their vehicle’s electrical system and demonstrate how to fix specific problems.

|

|

William B. Ribbens

Understanding Automotive Electronics

Society of Automotive Engineers Inc, Paperback, 2003-01 |

|

This illustrated how-to guide helps readers understand how electronic circuits and devices run important parts in automobiles. It explains how electronics affect engine performance, fuel economy, and emissions, and describes the role of electronics in speed control, ride control, and anti-lock braking.

|

|

Frank Munday

Custom Auto Electrickery: How to Work with and Understand Auto Electrical Systems

Graffiti Publications, Paperback, 2006-11-14 |

|

Custom Auto Electrickery will help the home-based enthusiast unravel the mysteries surrounding automotive electricals and electronics. Choco Munday explains every area of this field in easy to understand layman’s terms. From a simple rewire to installing and troubleshooting your own engine management system, it is all covered in this book.

|

|

Jensen

Schumacher SC-600A SpeedCharge High Frequency Battery Charger

|

|

This charger is fully automatic and uses advanced technology to charge up to twice as fast as conventional chargers. It will do a 6, 4, and 2 amp (maintenance) charge. Easy-to -read LED indicators displays battery charge status. 12V or 6V.

|

|

|

|